- Get link

- X

- Other Apps

Most hardware stores will carry moulds for making cement pavers but if you prefer you can make your own moulds out of plywood. Once the concrete dries you.

Make Your Own Mold For Concrete Part 1 Using Silicone And Cornstarch

Make Your Own Mold For Concrete Part 1 Using Silicone And Cornstarch

I chose sharp edges for this project so at this point I.

Making your own concrete molds. Provide a consistent and even surface. You can make your own concrete mold and use it to produce as many castings as you like for your outdoor projects. Create the edges of the form for the mold using cardboard or wood.

Making Molds from Rubber. Its a durable material that can withstand a lot. This kit is tailored to individuals that are trying mold making.

Both make polyurethane rubbers that come as two-part liquids resin and hardener. Its sort of like making pasta dough. This is the perfect tutorial for learning how to make your own concrete mold if this is the first time you have tried silicone as your concrete casting material.

Put the silicone in a caulking gun cut the end AND poke a hole in the tube then squirt it. Molds are ready for casting in a day and last in production. Casting concrete into rubber molds made with Smooth-On Rubber lets you make perfect copies of any original every time.

Reusable allowing for many multiples of copies. The amazing thing to use is alginate like what dentists use I used it for the life casting of the concrete hands It may be a bit tricky getting set up and managing to breath through a straw etc Search life casting and you will be amazed. Choose cardboard for molds with rounded edges irregular dimensions or simple straight-sided geometric shapes.

Make the concrete and pour it into the assembled molds. See more ideas about concrete concrete diy concrete projects. Use wood only for straight-sided shapes such as squares rectangles or triangles.

In a bowl that is not too precious as this may not come off put a pile of cornstarch at the bottom. Depending on the type of corners you want on the finished project you can also use silicone on the inside corners of the mold. The brand I recommend is Holdens.

Using a commercially prepared dry mix of. I recommend this one. Benefits Of Using Handmade Silicone Molds.

This will most likely be the most physically challenging part of making brick from concrete. You can create your own planter at home with 2 containers and a few tools. Concrete Mold Making Casting Make your own concrete molds forms texture and stamping mats with Polyteks wide selection of concrete mold making materials.

Once the mold is put together its ready for concrete. Seal the pores of the item to be cast in a mold. Now to make the molding compound.

The resin is what will add support to your rubber mold when its poured with concrete. There are two main suppliers of urethane rubber for concrete molds. Make Your Own Mold for Concrete Using Silicone and Cornstarch Frequently bendable concrete molds compressed wood and even froth offers the help to keep the thin overlay sheet in arrangement.

Requires mixing 2 parts at a 11 ratio. A handmade silicone mold is about as good of a concrete crafts mold as you can get. Jan 18 2020 - Explore Darrell Tiptons board concrete molds followed by 370 people on Pinterest.

Silicone is the best material for making a concrete mold if you want to make multiple copies. Or on the other hand the cover might be made sure about to firm feature plates using 2-by-four spines situated behind the overlay sheet. Then youll have to fill the mold with concrete and allow it to harden for 24 hours.

First youll have to create the mold with boxes or plastic containers. This guide will explain how to create and use molds specifically designed for concrete statuary. If you are thinking of making a mold of your face it IS possible.

Polytek manufactures a variety of polyurethane and silicone mold rubbers that are used worldwide for concrete applications eg formliners veneer stone manufacturing decorative surfaces and décor much more. Smooth-On rubbers can be applied right at the job site. They can be brushed on poured on or sprayed onto a model.

The rubber is for making the actual mold form of your model. Saving you time labor and material costs. This will give you a more rounded corner rather than sharp edges.

Through decades of research and development Polytek is able to offer one of the most comprehensive selections of flexible mold materials for concrete casting applications. You can find it here Holdens Latex Rubber. Liquid rubber is a great way to make durable perfectly smooth molds.

Making Your Own Concrete Molds Making A Silicone Mold For Concrete Crafts. Use this starter kit to make your first rubber mold for a small-scale concrete casting project of your choosing. Keep in mind however that you need to leave your paver inside the mould for at least two weeks so you need to have multiple moulds ideally as many moulds as the number of pavers you want to create unless you want the process to take an enormous amount of time.

17 Awesome Diy Concrete Garden Projects The Garden Glove

17 Awesome Diy Concrete Garden Projects The Garden Glove

How To Cast Anything With This Two Ingredient Mold A Crafty Mix

How To Cast Anything With This Two Ingredient Mold A Crafty Mix

Make Your Own Mold For Concrete Part 1 Using Silicone And Cornstarch

Make Your Own Mold For Concrete Part 1 Using Silicone And Cornstarch

17 Awesome Diy Concrete Garden Projects The Garden Glove

17 Awesome Diy Concrete Garden Projects The Garden Glove

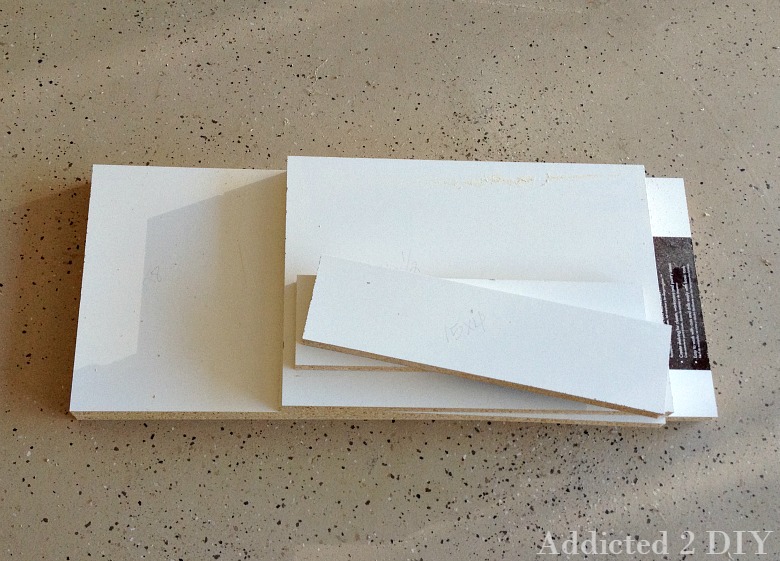

How To Build A Mold For Concrete Projects Addicted 2 Diy

How To Build A Mold For Concrete Projects Addicted 2 Diy

Make Your Own Mold For Concrete Part 1 Using Silicone And Cornstarch Concrete Diy Concrete Diy Projects Concrete Crafts

Make Your Own Mold For Concrete Part 1 Using Silicone And Cornstarch Concrete Diy Concrete Diy Projects Concrete Crafts

Diy Concrete Planters Cast In Reusable Molds Youtube

Diy Concrete Planters Cast In Reusable Molds Youtube

How To Build A Mold For Concrete Projects Addicted 2 Diy

How To Build A Mold For Concrete Projects Addicted 2 Diy

Easy Diy Concrete Planters Love Create Celebrate

Easy Diy Concrete Planters Love Create Celebrate

Make Your Own Concrete Molds Page 1 Line 17qq Com

Make Your Own Concrete Molds Page 1 Line 17qq Com

Cement Planter Molds Cement Flower Pots Diy Concrete Planters Concrete Diy Projects

Cement Planter Molds Cement Flower Pots Diy Concrete Planters Concrete Diy Projects

Easy Diy Molds For Concrete Planters At Home Youtube

Easy Diy Molds For Concrete Planters At Home Youtube

Concrete Mold Making Casting Polytek Development Corp

How To Build A Mold For Concrete Projects Addicted 2 Diy

How To Build A Mold For Concrete Projects Addicted 2 Diy

Comments

Post a Comment